BOLE DK SERIES

Developed in Germany with German engineering expertise and European advanced technology, BOLE’s DK Series Two-Platen injection molding machine offers precision molding of large components for automotive, housewares, and home appliances while offering a small footprint and higher productivity.

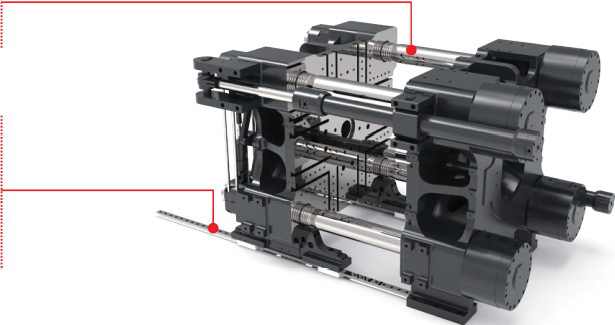

The DK Two-Platen’s patented “Floating” tie-bars means less connection between the tie-bars, thus increasing clamping precision while protecting molds and platens, guaranteeing the platens will not to break under high pressure molding conditions. The DK Two-Platen injection molding machines come in sizes ranging from 520-6800 tons. The BL6800 DK is one of the largest two-platen machines offered in the industry.

Precision & Stability

BOLE1s DK Series Operates independently with German engineering and performance for the highest quality for today’s demand injection molding applications.

More than I 00 tests run on more than 20 horizontal machines to increase speed, accuracy and stability.

The BOLE DK Series will become the first choice for automotive applications.

DK Series two platen machines incorporate high-precision, rigid linear guide coordinates with sliding block to support moveable platens, guaranteeing precision positioning of the platens and faster opening and closing speed. Eliminates the problem of splashing lubricating oil and improving the performance of the entire machine.

To get more information on presses from 520T – to 1100T click here

To get more information on presses from 1400T – to 2300T click here

To get more information on presses from 2300T – to 3500T click here

To get more information on presses from 4000T – to 6800T click here